Fast Formwork

A three week research, design, and fabrication project completed in partnership with two Master of Advanced Studies in Architecture and Digital Fabrication students at the ETH in Zurich that explored the possibilities of a segmented structure created by robotic deposition concrete 3D printing. Collaborators Aya Shaker and Noor Khader, under the supervision of PhD Researcher Ana Anton, developed a system that allowed for multiple elements to be printed separately and with integrated supports and a continuous print path to form an self-supported arch structure. As the initial exploration into their eventual thesis project, this study allowed us to push the boundaries of this advanced fabrication process. This was the first time multiple elements had been printed separately for assembly in this manner. From concept to fabrication, there were many lessons learned and ideas shared. My role was primarily concept development, rhino modeling, and fabrication as the simulation and programming was a proprietary process being researched by the university.

Summer 2019, GSAPP/ETH Summer Design Studio

Trevor Watson, Nina Baier-Bischofberger, Ana Anton

Trevor Watson, Nina Baier-Bischofberger, Ana Anton

3D model prototype created in Rhino and Maya. Scaled PLA 3D print prototypes exploring shape and texture.

3D model prototype created in Rhino and Maya. Scaled PLA 3D print prototypes exploring shape and texture.

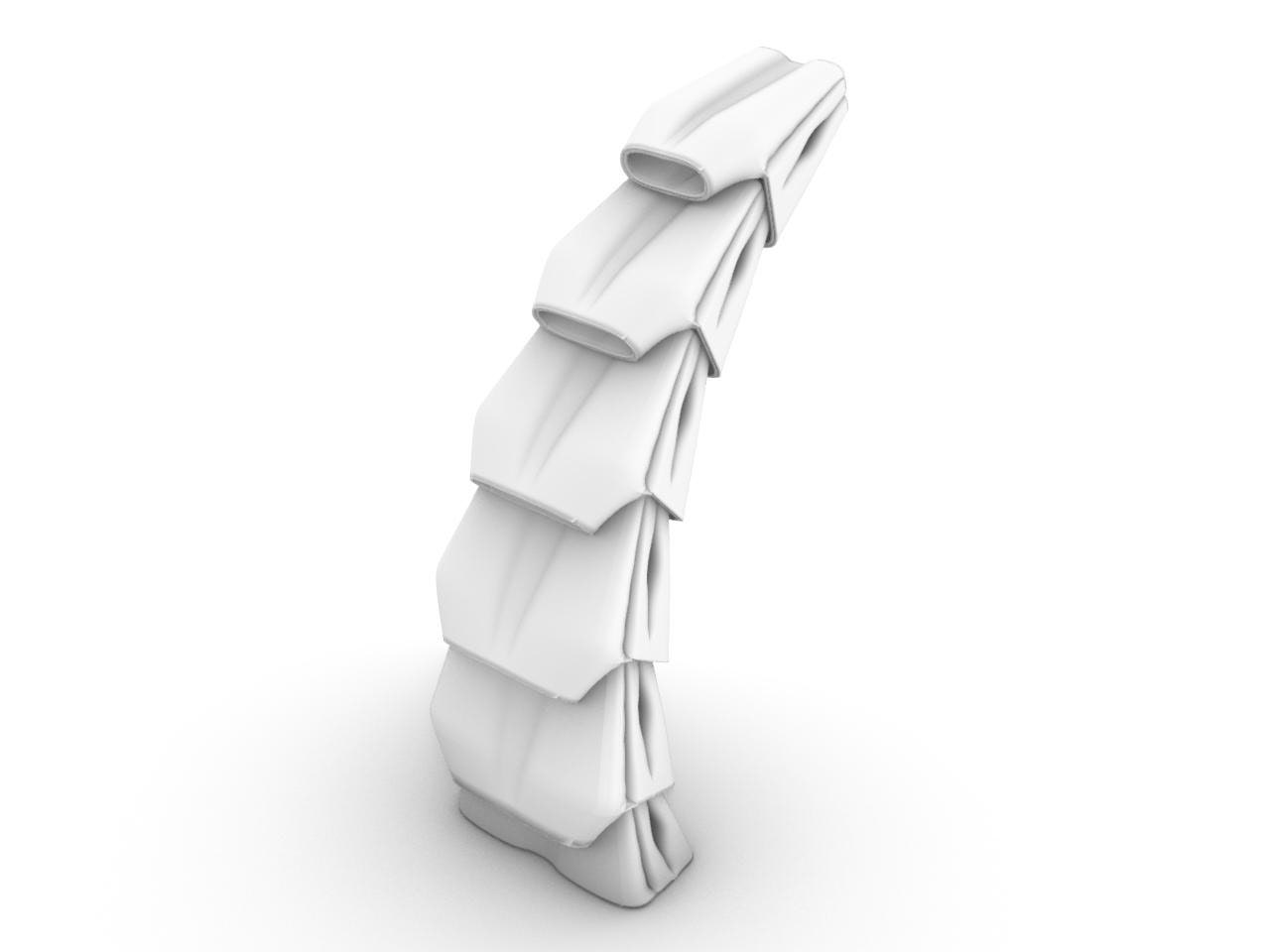

Final PLA 3D printed prototype. Created with a custom script to print in one continuous path to mimic Robotic Deposition printing.

All the completed segments printed in an hour and a half, weighing from 20lbs-65lbs.

Detail shot of completed segment showcasing the integrated structure created with the contentious path deposition process.

All the completed segments printed in an hour and a half, weighing from 20lbs-65lbs.

Construction of the segments in an attempt to create an arch from all five segments.